What is the Cycle Time Formula, How to use it

The difference between success and failure often hinges on the accuracy of your time estimates.

Picture this:

A high-priority request lands on your desk from a client who needs something done urgently.

Eager to please, you review the requirements and, based on initial assessments, promise a two-week turnaround; confident in your decision, you relay the deadline to your client, setting their expectations.

Next, you bring the ambitious deadline to your team, expecting a quick alignment on the plan, however, the reality is starkly different. The team is taken aback by the deadline, expressing concerns that the workload is significantly underestimated.

What was thought to be a 40-hour job is actually an 80-hour endeavour, suddenly, you're facing a daunting challenge:

an overpromised deadline, a potentially underdelivered project, and

a team stretched thin, battling frustration and burnout, including yourself

This scenario is all too common and highlights a critical pain point in project management: the dire consequences of inaccurate work scoping.

Not only does it put undue pressure on your team, but it also risks your reputation with clients, fear not, there's a strategic approach to prevent this from becoming your reality — mastering the cycle time equation.

What Is the Cycle Time Formula?

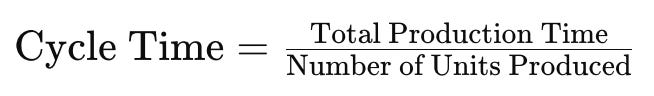

The cycle time formula is used to calculate the total time it takes to complete a task or process from start to finish.

The metric is crucial in project management, manufacturing, and service industries for optimizing efficiency and throughput, the formula for cycle time is expressed as:

where

The “Total Production Time” is the total time spent producing units. The timeframe includes all productive time from the start of the first process to the completion of the last process in a production cycle.

It's essential to accurately measure the time to ensure the cycle time calculation is correct.The “Number of Units Produced”, represents the total number of units completed and ready for delivery or sale during the measured period.

The Cycle Time gives you the average duration required to produce a single unit of output.

By understanding cycle time, organizations can identify bottlenecks, estimate delivery times more accurately, and improve process efficiencies.

Reducing cycle time can lead to increased capacity, lower costs, and improved customer satisfaction by meeting demand more effectively.

In various industries, the specifics of what constitutes "production time" and a "unit" might differ; for instance, in software development, a "unit" could be a feature or update, and "production time" could include design, coding, testing, and deployment, instead in a manufacturing context, a unit would be a physical product, with production time encompassing all steps from raw materials to final product assembly.

The benefits of calculating cycle time

Understanding and applying the cycle time formula can transform your business operations and strategic planning below, are the major advantages of accurately calculating cycle time:

Enhanced Profitability Through Cost Efficiency

Prioritizing the optimization of cycle time naturally leads to reduced operational costs and heightened profitability.

A deeper insight into time allocation across processes can reveal opportunities for cost reduction, for instance, an organization could boost its pretax profits from 2% to 13% by leveraging cycle time analysis alongside other lean methodologies.

Stabilized Production Rates

A thorough grasp of your production processes allows for the implementation of measures that normalize production rates. Standardization helps avoid the pitfalls of overproduction or underproduction, ensuring a steady flow of outputs.

Boosted Customer Satisfaction

Misestimating delivery times can strain customer relationships, by calculating cycle time accurately, you gain the ability to set and meet realistic deadlines, enhancing trust and satisfaction among your clientele.

Streamlined Team Operations

Analyzing cycle time data sheds light on potential inefficiencies within your team’s workflow. Identifying areas where the process lags can lead to adjustments that enhance overall efficiency, such as optimizing production batches for faster delivery times.

Accurate Project Scoping

Without a clear understanding of the time required for tasks, projects can easily be mis-scoped, leading to team frustration and customer dissatisfaction. Cycle time provides a factual basis for project estimates, reducing the likelihood of underestimating the scope of work.

Competitive Edge in the Market

In a competitive landscape, the ability to deliver quickly and reliably can be a significant differentiator. Utilizing cycle time data enables you to refine your production timelines, staying ahead of competitors and retaining customer loyalty through dependable service.

Informed Resource Allocation

By evaluating the cycle time for various tasks, you can assess the cost-effectiveness and value of different processes; the insight allows for strategic resource allocation, focusing efforts and investments on the most impactful areas of your operation.

The challenge of calculating the Cycle Time

Implementing the cycle time calculation effectively encounters various challenges beyond communication siloes, task prioritization issues, and supply chain disruptions; in my experience:

Data Collection and Accuracy

Gathering the necessary data to calculate cycle time can be complex, especially in environments where processes have not been previously measured or where data is not digitally captured. Ensuring the accuracy of the data is crucial since inaccuracies can lead to misinformed decisions, skewed cycle time calculations, and ultimately, inefficiencies rather than improvements.

Variability in Tasks or Production Processes

Not all tasks or production processes are the same, and variability can significantly affect cycle time calculations. Factors such as differences in complexity, worker skill levels, machine efficiency, and even external influences like supply delays can introduce variability that makes it challenging to calculate a reliable average cycle time.

Change Management Resistance

Introducing new metrics and processes to calculate and optimize cycle time can meet with resistance from both management and team members.

Change resistance is often rooted in comfort with the status quo, fear of the unknown, or concerns about increased workload, overcoming this resistance requires effective communication, training, and demonstrating the value of cycle time analysis to all stakeholders.

Integrating Cycle Time with Other Metrics

While cycle time is a valuable metric on its own, its full potential is realized when integrated with other performance metrics like lead time and takt time.

However, aligning these metrics and using them in a cohesive manner can be challenging, especially in organizations where these concepts are new or where existing systems do not support integrated analyses.

Resource Constraints

Accurately calculating and acting on cycle time improvements often require investments in technology, training, and possibly additional personnel.

Organizations with limited resources may find it challenging to allocate the necessary funds and time to implement cycle time analysis effectively, particularly if the immediate benefits are not clear or are perceived as low priority compared to other initiatives.

Scalability and Adaptability

As organizations grow and processes evolve, previously established cycle times may become outdated. Ensuring that cycle time calculations remain relevant and reflective of current operations is crucial it requires a commitment to continuous improvement and the ability to adapt and recalibrate processes as necessary, which can be challenging in rapidly changing or scaling environments.

Addressing these challenges requires a strategic approach, including investing in the right tools and technologies, fostering a culture of continuous improvement, and engaging team members at all levels in the process of optimizing cycle time for better efficiency and competitiveness.

Keys difference between Cycle time vs. takt time vs. lead time

The difference between cycle time, takt time, and lead time is essential for effective project management and process optimization.

While these metrics are interrelated, they each offer unique insights into the efficiency and effectiveness of production and service delivery processes, as said, Cycle Time refers to the amount of time it takes to complete a specific task or process from start to finish.

The metric focuses on the production or work process itself, measuring the speed at which tasks are completed or products are made.

It's a critical metric for identifying bottlenecks and inefficiencies within the production process and for setting realistic expectations for task completion times, instead, Takt Time, is a measure of the rate at which products must be completed to meet customer demand.

Takt Time It is calculated by dividing the available production time by the number of units the customer needs; it is fundamentally about aligning production speed with customer demand, ensuring that production is neither too fast (leading to excess inventory) nor too slow (resulting in shortages).

It's a demand-driven metric that helps balance production flow with customer requirements.

The Lead Time measures the total time from the customer's request or order to the delivery of the final product or service.

It encompasses all stages of the process, including order processing, production, and delivery. Lead time gives a comprehensive view of the customer experience from order to delivery, highlighting areas for improvement in the overall process to reduce waiting times and enhance customer satisfaction.

Key Differences

Focus

Cycle time focuses on the efficiency of the production process, takt time on meeting customer demand, and lead time on the total customer experience from order to delivery.

Calculation

- Cycle time is based on the production process itself (total production time divided by the number of units produced).

- Takt time is calculated by dividing available production time by customer demand.

- Lead time encompasses the entire process from receiving an order to delivering the product or service.

Application

Cycle time is used to assess and improve process efficiency, takt time to align production with demand, and lead time to evaluate and enhance the end-to-end customer experience.

A story from my experience

In the heart of London, nestled among tech giants and startups, was a promising new app development company, InnovateX (Fantasy name) At its helm was Jordan (fantasy name as well), a visionary project manager with a passion for technology and a drive to make InnovateX the next big name in the industry. Jordan was known for their ambitious goals and their belief in pushing the limits of what was possible.

The story begins with an exciting yet daunting challenge. InnovateX landed a high-stakes project to develop an innovative app for a major retail client, promising to revolutionize the shopping experience. The client, thrilled by the pitch, set an aggressive launch date to capitalize on the upcoming holiday shopping season. Eager to impress and confident in their team's abilities, Jordan committed to the timeline without conducting a thorough review of the project's scope and requirements.

As work commenced, Jordan decided to apply the cycle time formula to manage the project, aiming to streamline processes and ensure timely delivery. However, Jordan overlooked the importance of accurately calculating and understanding cycle time, not accounting for the variability and complexity of app development tasks. They failed to gather sufficient historical data on similar projects, which led to an overly optimistic estimation of how quickly tasks could be completed.

The initial weeks saw the team working at a sustainable pace, but as the project progressed, it became evident that the estimated cycle times were far from reality. Tasks that were expected to take a day extended into a week, and the intricacies of integrating advanced features were vastly underestimated.

Despite these warning signs, Jordan insisted on sticking to the original timeline, driven by the commitment made to the client. The decision forced the team into a gruelling schedule of long hours and weekend work, draining their energy and morale. The lack of communication and collaboration further exacerbated the situation, as team members became increasingly isolated, focusing only on their immediate tasks to meet the ever-looming deadline.

As the project neared its supposed completion, the quality of work began to suffer. Bugs and performance issues piled up, and the team, now burnt out, struggled to address them adequately. The final app was delivered to the client on time but was riddled with issues, falling short of the revolutionary product that had been promised.

The aftermath was grim. The client, disappointed with the product's quality, withdrew from the project, leaving InnovateX to face significant financial and reputational losses. The team, once vibrant and enthusiastic, was left disheartened and fatigued, with several key members choosing to leave the company in search of healthier work environments.

Jordan's failure to accurately calculate and respect cycle time, compounded by a lack of flexibility, effective communication, and team care, led to a project that not only failed to meet its ambitious goals but also caused lasting damage to the team and the company.

This story serves as a cautionary tale about the consequences of overlooking the fundamental principles of project management and the vital importance of supporting and listening to one's team.